scuff rub tester|astm d5264 rub test : factories Power Supply (Current : Max 5 Amps) : 230 Volts A.C., 50 Hz. Clean power. Not available in 110 V AC supply. See more Diário Escolar - CAEd Digital

{plog:ftitle_list}

webEncontra, compara os preços e compra os teus produtos favoritos no KuantoKusta. Tudo o que precisas em Informática, Casa e Decoração, TVs, e muito mais.

Base Weight : 1. 2856 grams. Equivalent to 2 psi rubbing pressure. Addon Weights : 1. 714 grams. Equivalent to 0.5 psi rubbing pressure. 2. 1428 grams. Equivalent to 1 psi rubbing pressure. 3. 1428 grams. Equivalent to 1 psi rubbing pressure. See more

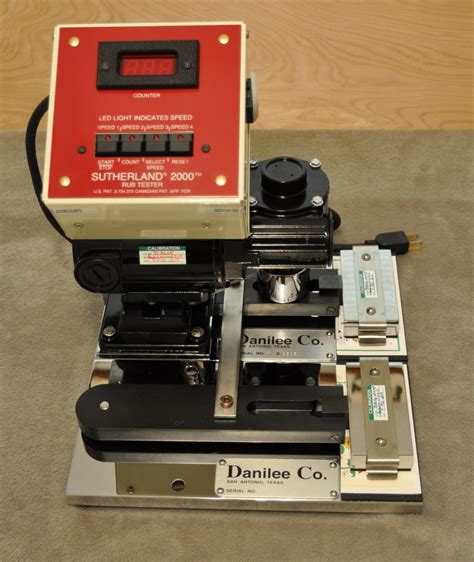

VXC2 with 2 psi rubbing pressure (fixed, base weight). VXC4 with 2 to 4 psi rubbing pressure (fixed + addon weights) See morePower Supply (Current : Max 5 Amps) : 230 Volts A.C., 50 Hz. Clean power. Not available in 110 V AC supply. See moreThe SUTHERLAND® 2000™ Rub Tester is a motor-driven abrasion testing instrument for moving a weighted test strip over a printed specimen through an arc. The SUTHERLAND® 2000 “Dual” Tester provides the same robust functionality of a single tester while adding the ability to test two specimens .

Using the Sutherland Rub Test, our engineers can determine the amount of scuff or abrasion damage that may occur to printed materials during shipment, storage, or handling. This test procedure can simulate the effects of human use in .Sutherland Rub Tester. This is commonly used to determine the amount of scuff or abrasion damage associated with transit shipment, storage, or handling of printed packaging. The .

The SUTHERLAND® 2000™ Rub Tester incorporates a digital counter with a fiber optic sensor to ensure the accuracy of the number of rubs desired and the instrument will shut off .Westpak offers a variety of methods for testing products and materials for abrasion resistance. These tests are the industry standards for evaluating scuff or rub resistance of printed or .

The ASTM D5264 Sutherland Rub Test is typically used to evaluate the ability of printed labels to resist scuffing and smearing under controlled conditions. A test label is rubbed repeatedly against another surface (such as another label, .

An affordable and proven abrasion testing instrument, the SUTHERLAND® Ink Rub tester has been the industry standard for decades. It is designed to evaluate the scuffing or rubbing resistance of the printed or coated surface of paper, .A laboratory rub proof tester is a tool for comparing the rubbing, scuffing and marking of inks and coatings on commercial print and packaging. It can be used as part of quality control in a production environment or an aid to development .A scuff-resistance test can be used to mimic the abrasion resistance of printed, painted, or polished services. This method may be used to replicate the effects of continuous contact or dual surface abrasion in a number of industries. In this .

Scuff resistance tester is a very accurate instrument to evaluate the rub resistance between two stickers or any general printed material. The term scuff implies the rubbing of two materials against each other. Scuff tester rubs two . For printed labels, the rub test gauges the amount of abrasion or scuff that may result during shipping, handling or storage. The test may be used for the labels of pharmaceutical products and medical devices, as well as the .The Testronix scuff tester rubs two printed objects individually, each face to face in the same plane at a continuous speed and standard load pressure. This lab testing instrument is used to test the abrasion properties of various kinds of surfaces. It is an essential instrument in quality control and research & development departments for many . VERTEX Make Scuff Tester, For more details contact us at [email protected]

Scuff test (patra rub tester) - video guide - by packtest.co. Digital rub proof scuff tester, 220 volts, model no.: pap-40. Psr-295 scuff resistance tester; Torque tester; 220v ink rub tester, for printing industries; Digital ink rub resiatnce tester, 220 v ac 50hz; Digital scuff tester, 220 vac;Printed Labels & Rub Testing - For printed labels, the rub test gauges the amount of abrasion or scuff that may result during shipping, handling or storage. The test may be used for the labels of pharmaceutical products and medical devices, as well as the characters on keypads, for example. These labels must be legible and stand up to wear over .Rub / Scuff Test Scuff Tester / Rotary Rub Tester VXC Series This equipment is intended to evaluate the quality of printing on paper or paper board. To evaluate Abrasion Resistance or Colour Transfer from printed / coated surface due to rubbing or scuffing action experienced by printed material during production, handling, or transportation. It gauges the level of scuff or abrasion that may result when products are stored, handled, and shipped. Examiners can use this device to test labels using a specified speed equivalent to a particular period of use or storage. Speed Settings. The Sutherland 2000 rub tester features four different speed settings:

The Rub Proofness Tester, also known as the Rub/Scuff Tester, is an indispensable tool designed to address this challenge. This article delves deep into the Rub Proofness Tester, exploring its functionality, applications, benefits, and significance in quality control. Standard Practice for Abrasion Resistance of Printed Materials by the Sutherland Rub Tester D5264-98R19 ASTM|D5264-98R19 . of printed materials to determine if the product offered for sale meets some predetermined standard for abrasion or scuff resistance. Scope.

Manufacturer of Digital Scuff Ink Rub Resistance Tester - Digital Ink Rub Resistance Tester, Scuff Tester offered by Nova Engineers And Instruments, Mumbai, Maharashtra. Nova Engineers And Instruments. Nalasopara East, Mumbai, Maharashtra GST No. 27ATAPC4886B1ZY. Call 07942550287 93% Response Rate. Send Email. Home;Rub PR oofness TesTeR (Scuff Tester) Rub Proofness Tester, measures how effectively printing ink adheres to paper or board. Conforming to BS 3110, the instrument evaluates the extent of color transfer from printed or coated materials due to rubbing – a condition which frequently occurs during the handling and shipment of packaged goods.Introducing our new BOTTLE CAP ADAPTER for our SUTHERLAND 2000 Rub Tester! We can make this custom fit for your caps or any other type of lid you require abrasion and rub testing for. SUTHERLAND® 2000 Dual Rub Tester. SUTHERLAND 2000 Rub Tester shown with the Dual Option. Allows for testing two specimens at the same time! The rub and scuff test takes place before, during and after the actual production of your labels. The following procedure outlines the equipment, materials and steps involved in performing an accurate and repeatable rub .

Although the SUTHERLAND® 2000™ Rub Tester was originally designed to fill a need for testing the scuffing or rubbing resistance of inks used in the paper and paperboard industries; today it is being used by manufacturers of cleaning compounds, waxes, floor tile, film, and many other items. The test results are reproducible.

sutherland rub abrasion test

RT-01 Ink Rub Tester is applicable in abrasion resistance test of printed materials, PS boards and coating layers of other products. It can effectively analyze the abrasion resistance, ink layer fastness and the coating rigidness .Scuff Tester / PATRA Rub Tester This equipment is intended to evaluate the Rub Proofness of prints on paper or board. It can also be used to measure / evaluate Colour Transfer from printed / coated surface during rubbing. The application can be extended for measurement of abrasion resistance of some Plastic materials /

Alternatively known and abbreviated as the “Sutherland Rub Test”, this test uses an instrumented specifically designed simply for this test. The Sutherland Rub Test can determine the amount of scuff or abrasion damage that may occur to printed materials during shipment, storage, or handling. This test procedure can simulate the effects of . The ink rub tester itself is a motorized piece of equipment that delivers a certain amount of strokes to see whether a specimen scuffs or runs. Again, the abrasions are not some tucked away recollection that should be analyzed. . Along with TAPPI T 830-2018 there are other forms of rub and scuff tests. These tests include: Abrasion loss of .Procedure for Operation of SUTHERLAND® 2000 Rub Tester Page 1 Description the number of rubs for a given test. Simply enter the The tester is a motor-driven instrument for moving a weighted test strip over a printed specimen through an .

Lloyds laboratory Rub Resistance Tester is a tool for comparing the rubbing, scuffing and marking of inks and coatings on commercial print and packaging. . It is designed to determine the quality of adhesion, and scuff resistance of ink to paper surfaces, plastic and aluminium film. It will dry or wet rub the sample until it achieves the pre .

The rub and scuff test takes place before, during and after the actual production of your labels. The following procedure outlines the equipment, materials and steps involved in performing an accurate and repeatable rub test: A rub testing machine is required. If your printer is producing beverage bottle labels they should have one.Ink Rub Tester (also known as the Sutherland Rub Tester), is used to test printed substrates such as plastic films / foils / labels / papers or paper boards for resistance to scuffing / rubbing / smudging when 2 samples are rubbed against each other in a linear motion, under a defined pressure, at a defined speed for a defined number of rubs.Functional Rub is a term of embracing a number of miscellaneous uses for the SUTHERLAND® Rub Tester. Ink, which is acceptable under the outlined test procedures, may fail under exposure to foreign liquids or pastes. For example, certain inks might be tested to conform to specifications such as “one rub, Cod liver oil” or “three rubs .By conducting a scuff resistance test on the materials, one can easily determine how resistant your labels or printed material is against rubbing. This information can be extremely helpful in deciding whether the material is suitable to be used in the industry or not. In this blog post, we will discuss brief information about the use of a scuff resistance tester and how this quality lab .

To perform the test using Presto’s Rub Scuff Tester, take two samples of substrates and rub them against each other in the same plane using the constant pressure of 2 p.s.i. with a fixed speed of 60 RPM. The number of strokes or rubs can be .

how does a wood moisture content meter work

WEBdoTERRA は、自然の恵みを活用したエッセンシャルオイルやウェルネス製品を提供す .

scuff rub tester|astm d5264 rub test